Train wash plants and control emission toilet (CET) systems, together with basic equipment for train depot facilities, have been developed by Aquafrisch to support the expansion of the railway industry. Train wash plants can be customised to attend specific needs in rolling stock.

Aquafrisch is a service-oriented company. From the earliest stages of project design to after-sales maintenance services, Aquafrisch is focused on customer confidence. The company aims to generate the best value for customers by developing its own equipment and services, or working together with leading partner companies in international markets, across more than fifteen countries.

Aquafrisch offers a wide range of equipment manufactured in its own factory. This is complemented by a distribution network with international commercial partners. This combination achieves a complete offer that includes high levels of quality and technological innovation while ensuring high-quality service standards.

Train wash plants with modular technology

Aquafrisch designs train wash plants using modular technology that focuses on robust and reliable equipment as well as low maintenance requirements. Modular technology suits metro trains, trams, high-speed trains, locomotives, and light and mainline rail applications. Aquafrisch develops both fixed (including the stop&go system) and mobile train wash plants. Modular possibilities include:

- Bi-directional wash

- Pre-wet arches

- Chemical wash arches

- Side wash brushes (vertical)

- Side wash brushes (horizontal)

- Front / rear / roof wash brushes

- Eaves / skirts wash brushes

- High-pressure wash

- Recycled water rinse arch

- Demineralised water rinse arch

- Wax arch

- Under wash

- Drying system

- Water recycling systems

Additionally, the technical room supports all components that run the machinery, including intuitive touchscreen control for a user-friendly interface with the maintenance team.

Train Wash Plants offer many possibilities for specialist equipment, including traffic indicators, train identification systems, motion-sensors, train driver information displays, touchscreen control-panel, speed control systems and monitoring options.

All train wash plants can be tailored to customers’ needs, and designed together with water treatment systems. These include either recycling for environmental care so water can be reused, or demineralising processes such as osmosis and softeners for best rinsing results.

Control emissions toilet systems

CET systems were developed by Aquafrisch to make the removal of waste from train toilets an easy and safe cleaning process. The process can be used with either large fixed installations or single mobile units.

Aquafrisch CET systems enable tailored solutions for tracks up to 500m long and multiple servicing points. The extracting and refilling process is designed with vacuum technology to ensure optimal working speed and a very low maintenance profile. Piping installations can be adapted to suit the space available and either built in stainless-steel or PVC materials. The system processes effluent, potable water, clean water and chemical products (including biocide) as necessary.

CET systems are controlled with easy to use touchscreen control panels, allowing specific programmes for every type of train. The programme can be based on the number of toilets on the train, litres required for discharge-flushing-charge, and biocide mixture.

Bogie wash plant

Aquafrisch offers different solutions for bogie wash, including systems with or without cabin and different degrees of automation. Our washing system include oscillating piping engines for pressurized water spray, allowing uniform distribution on all parts of the equipment to be washed.

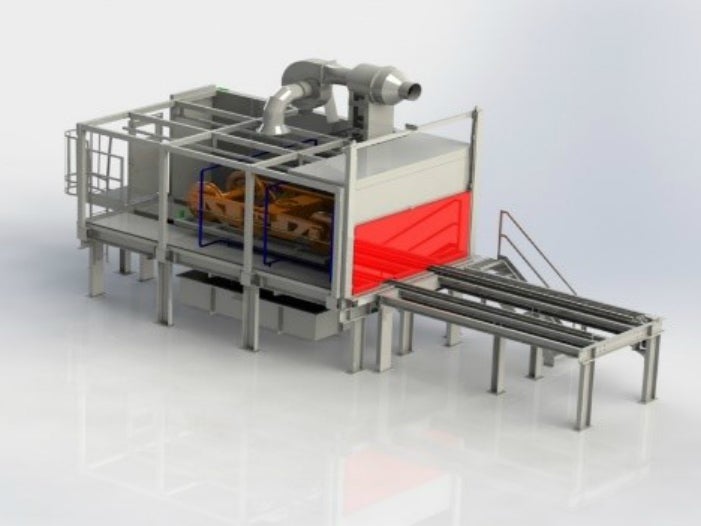

Internal rail tank wash

Aquafrisch manufactures customised installations for washing internal rail tank wagons. Integration of new technologies with high quality components has permitted the development of an efficient washing process based on an extensible system of rotary heads, fed with hot and cold high water pressure (up to 200 bars).

Waste water treatment plants

Aquafrisch is experienced in wastewater treatments and provides a wide range of solutions for train depot needs, from water recycling systems to high-proficiency wastewater treatment plants (including biocides), tailored to customer’s needs.

- Effluence Treatment plant: The use of biocides in train toilets, solvents for removing graffiti, tank cars, etc. make the treatment of water from the railway workshops a complex task that should combine different purifying processes to achieve the appropriate discharge parameters.

- Water recycling system: The system treatment allows the reuse of up to 80% of water used in the washing of railway vehicles.

- Reverse osmosis and Water softener: Many of the processes taking place at the workshops require good water quality to ensure optimum finishing (softening, demineralisation, reverse osmosis, MBR processes, etc.).

Tank interior washing systems

In the cold periods, the ice present in the trains makes it difficult to maintain and can cause problems in their operation.

For this reason, Aquafrisch has designed a special integrated system using a unique heater to achieve a faster solution and greater operational efficiency in removing the ice. The system consists of a metal structure on which diffuser nozzles are placed longitudinally to cover the entire surface of the bogies.

The de-icing system is fully automatic and different programmes can be configured depending on the amount of ice to be removed in order to meet individual needs.

Train depot equipment

Aquafrisch is proud to have a variety of train depot equipment available, including the sand system, rain test systems, lifting jacks and measuring devices for local market.

In addition Aquafrisch has a great network of high-standard European partners, which allow it to offer a complete range of rail equipments to the market.

Please use the form below to send Aquafrisch your business enquiry.