EMEF-Empresa de Manutenção de Equipamento Ferroviário, S.A., is the main Portuguese Company in the Railway Maintenance Sector and develops it`s activity in five main fields:

- Maintenance, repair and refurbishment processes – on railway rolling stock material and equipment

- Preventive and corrective maintenance

- Build-up, rehearsal and commissioning

- Freight wagon design and manufacturing

- Innovation

EMEF has been Quality Management System certified since 2000, currently in accordance with EN ISO 9001:2008 standard, covering our global activity, carried out in all of our workshops and central services.

Maintenance, repair and refurbishment

A wide experience in the sector of maintenance of the rolling stock fleet of CP-Comboios de Portugal – diesel as well as electrical – allows EMEF to develop the best solution for the maintenance of any type of rolling stock:

- Preventive maintenance

- Corrective maintenance

- Emergency interventions

We also undertake implementation of the RCM reliability centered maintenance (RCM) methodology in the CPA400 trains (Pendolinos) and in other rolling stock material.

Freight wagon`s design and manufacturing

A wide experience in the sector of the freight wagon`s design and manufacturing, as well as, a set of technical and operational solutions make EMEF able to supply “turn-key” solutions, by having the following abilities:

- Engineering design in accordance with customer needs

- Production with high-level quality standards

- Static and dynamic tests – TSI procedures and requirements

- Supply

Railway innovation

We also offer the following services:

- Innovation in the Railways business with real, customer tailored and successfully tested field applications

- University / industry interface experience applied to real problem solving

- Active participation with railways experience in Framework European Projects (FP7)

- New railways maintenance technologies for optimized rolling stock life-cycle cost

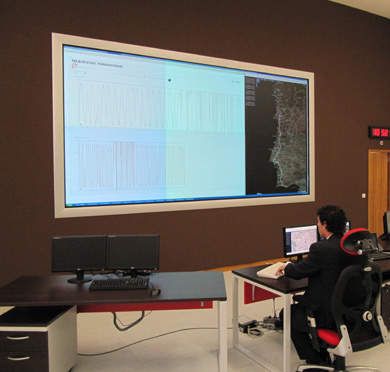

- Condition-based maintenance – telemaintenance – reliability centered maintenance with TRAINix © solution. Technology applied to existing and new rolling stock material

- Remote energy metering system for energy efficiency ecodriving solutions

- Wireless on-board CCTV and wireless video transmission to distributed ground datacenters

- Power electronics project and repair expertise

- Railways re-engineering projects for alternative solutions in automation and electronics systems according to operation specific needs

- Railways Telemaintenance TRAINix© and electronic loogbook eDTB© patents by EMEF Innovation Unit – UITF