Since 1987, Sontech has delivered noise-control engineering services and supplied sound-damping materials. A world leader in micro-perforated panel (MPP) technology, we specialise in multi-functional acoustical panel technology for trains.

Sound-reduction wall panels for trains

According to acoustic physics the noise-reduction property of a partition wall is dependant on the total weight of the wall. The development of new Sontech Acousti-dB sound-reduction wall panels for trains started with the idea that part of the mass can be used to improve other properties, such as stiffness and acoustical absorption.

A new FEM technique has been used to simulate how to allocate the mass to increase the stiffness and the absorptive properties without decreasing the sound-reduction properties. This is accomplished by building a composite panel with a core made of porous, low-density material, a back surface laminated with a non-porous high-module sheet (typically AL) and a front surface made of a micro-perforated but still high-module stiffening sheet.

Micro-perforated wood sound-reduction panels

A purely metal surface is rarely accepted as an interior design element in passenger areas. This has led us to develop a micro-perforated wood ‘acustiwood’ sheet that can keep the acoustical comfort and add a softer and warmer feeling. The tiny micro-perforations give the necessary breathability without losing the wood’s look and touch.

Micro-perforated wood sound-reduction panels are backed by an aluminium sheet so that strength and robustness can be maintained, and to ensure compatibility with flammability criteria.

Laminated or painted sound-reduction panels

Another approach is to laminate textile materials on to the MPP metal, or to use painted MPPs, which have been developed to a new level using powder coatings that will not clog the necessary holes. These solutions ensure a wide range of possibilities for choosing appropriate texture, colour and pictorial patterns for most demands.

Sound-reduction panels for engine cooling systems

Depending on drive-engine type, there are different solutions to reduce the noise emitted. In all cases the engine compartment needs to be encapsulated in order to keep the noise emission down. The encapsulation is usually designed so that it will at the same time encapsulate the heat generated, which in most cases is not desired. Therefore controlled engine cooling will be necessary, which usually involves noise-generating sources like fans, heat exchangers and ducting.

General engine compartment linings have to meet the requirements of high absorption combined with non-flammability, high temperature resistance, cleanability, and robustness for durability of at least 15 years. The MPPs are not restricted to wall lining but have also been successfully used for tight-fitting shields and stand-alone baffles if space is available.

Sontech is currently participating in an EU-sponsored project, ECOQUEST, which is targeting the optimisation of efficient and quiet cooling systems for rail-borne engines. In this project the MPP has been found to have many advantages that are preferred in these systems.

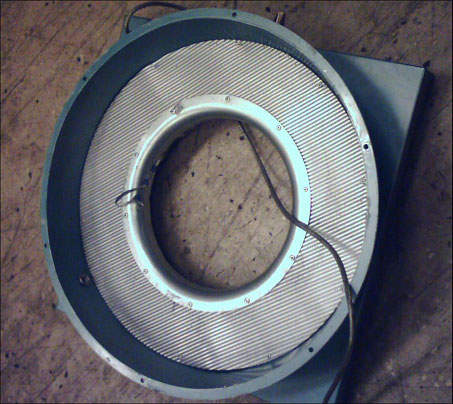

Sound-absorbing end caps for ventilation fans

In the case of diesel engines a special problem is the problem of damping the exhaust combustion gas. MPPs made of steel or stainless steel have proven to be efficient, durable and cost-effective when used correctly in the muffler design. Several muffler manufacturers are currently developing products based on the successful results of Sontech sound-reduction panels.

Exterior noise-damping covers for trains

All rail-bound vehicles are bound to comply with the EU directives that set limits to the noise emitted to surroundings. Locomotives, wheels and bogie systems and rails all contribute to this phenomenon.

At the Swedish Centre for ECO2 Vehicle Design, one important project area is handling noise emission. Sontech has participated in the design of noise-damping covers (‘skirts’) which shield the noise generated and amplified between the ground and the chassis of the train. Again, resistance to weather, cleanability and durability is of the highest importance.

Noise wall barriers for railways

Noise emission from rail vehicles is a particular issue in residential areas of towns that use high-traffic density trams, subways and local trains. A way to solve the problem is to use noise wall barriers.

Beside standard 2m-3m high noise wall barriers, which use MPPs to absorb material toward the rail, Sontech has developed a micro-sized noise wall barrier which is mounted very close to the rail without interfering with the security limits of the moving vehicle.