Machining of railroad wheels has been a long-standing speciality of MAG, and we have developed into a market leader for this field.

The MAG product spectrum ranges from high-torque vertical turning machines (MAG Hessapp) to flexible machining centers (MAG Hüller Hille) and continues to turnkey, single-source responsibility manufacturing lines supplied by MAG Hessapp.

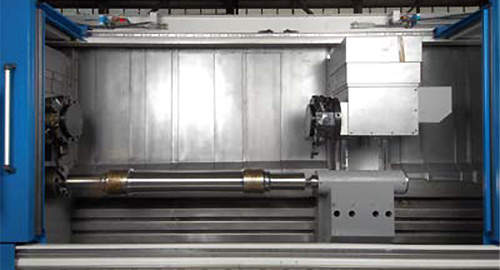

Twin-spindle rail wheel manufacturing machine

For wheel manufacturing in limited batch sizes, MAG Hessapp offers a twin-spindle machine with reciprocating tool heads that allows for loading / unloading of one spindle, while machining a part on the adjacent spindle. This concept leads to dramatically improved production rates.

High-volume railroad wheel manufacturing

High-volume manufacturing of railroad wheels is preferably done in three chucking setups, where step one and two turning utilize the same machine. The subsequent boring task is traditionally performed on a machining centre.

Alternatively, the wheels can be rough machined on turning machines and then transferred to turn mill centres for a combined boring and finish turning application.

Advantages include:

- Long-lasting experience on machining of railroad wheels

- Wide variety of vertical-turning machines

- Single-source supplier for entire process and manufacturing system

- Machine tool products designed for the highest rigidity and output

Railroad wheels or wheelset axles manufacturing equipment

The MAG product portfolio offers the most suitable machine tool products for manufacturing both railroad wheels and wheelset axles, from the same group of companies. MAG Boehringer and MAG +FMS+ have provided railroad axle manufacturers with innovative process solutions and class-leading CNC equipment for many years.

Semi-CNC teach lathes, length cutting and centring machines, and flexible turning cells

From semi-CNC teach lathes (MAG Boehringer) to purpose-built length cutting and centring machines, and on to flexible turning cells for rough and semi-finish machining (MAG +FMS+), our product line offers comprehensive solutions for a multitude of different applications.

Advantages include:

- Comprehensive line of flexible, horizontal turning machines

- Machine tool products designed for highest rigidity and output

- Cooperation with a partner highly experienced in shaft machining

About MAG

MAG is a leading machine tool and systems company serving the durable-goods industry. Utilizing a comprehensive line of equipment and technologies in combination with diverse process engineering knowledge, MAG provides tailored manufacturing solutions to customers in the rail, aerospace, machining, automotive, heavy equipment and energy sectors.

We have brought together a large portfolio of highly-recognized and well-respected brands with installations throughout the world providing unique technologies and services to meet the diverse needs of the key industrial sectors. A growing number of leading international companies are relying on the impressive, innovative power of MAG to ensure their technological leadership and prepare for future challenges.